Understanding static pressure in an HVAC system can feel like navigating a maze of technical jargon. But considering how critical it is to the HVAC design and operation, it’s always a good idea to have a clear picture and at least a working knowledge of what static pressure is and how it affects the system’s performance.

For brevity, this article serves to define static pressure, explain its function, highlight its impact on the HVAC system and outline how it’s measured and monitored.

So, let’s break it down.

What Is Static Pressure in an HVAC System?

Static pressure is one of the important elements of any good functioning HVAC design. It is simply the counteracting of airflow to the ductwork. If the static pressure is too little or too much, the HVAC System may fail or run without conserving energy efficiently. The force pushing the air must be more powerful than the counteracting force.

In technical terms, static pressure is the quantity of pressure calculated in inches of water when air passes through an object, in this case, the ductwork. It’s impractical not to have any counteracting and the goal is to keep it under control.

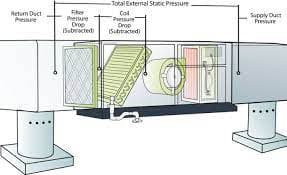

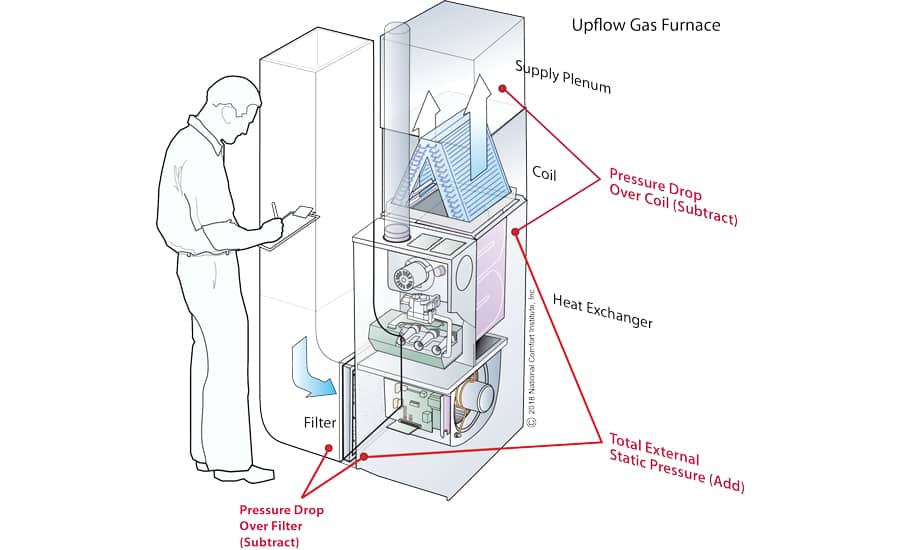

As a contractor, you need to understand the concept of static pressure in order to help homeowners understand how their heating and cooling system works and the steps they may need to take in case of system failure. An illustration of how the workflow occurs is shown in the images below:

How to Calculate Static Pressure

Simply put, static pressure is like the blood pressure for ductwork. As an HVAC system installer, static pressure gives you a sense of the system’s health. Using the blood pressure example, let’s say the system is 0.5 WC (water column); it corresponds to blood pressure 120/80, which means the system is working perfectly fine.

If you take the 0.5 WC and multiply it by 2, you’ll get 1 WC and 240/160. This shows that the HVAC system has extreme airflow resistance. If the reading is 0.75 WC, for example, multiplied by two, you’ll get 1.5 WC and 180/120, which means that the system’s static pressure is still too high.

Just like the human body, if the static pressure is excessive, it will not function properly as the HVAC system will struggle to push air through the ductwork. This will result in a house being either too hot or too cold and an increased energy bill. If the resistance becomes overwhelming, no air will flow through the system and it will stop.

Contractors and installers use manometers to calculate static pressure. Usually, small holes are pierced in the ductwork and the manometer sensor is placed into it. Every HVAC manufacturer is required to calculate and disclose the pressure drop status of their equipment. This helps installers know whether the pressure will drop before or after a coil when installing these systems.

What is the Ideal Static Pressure?

High or low static pressure affects your HVAC system. Extreme high pressure will cause a lack of air to flow through your system making it stop functioning. Low static pressure could suggest leaking ductwork, low fan speed, separated ductwork and misplaced filters.

The perfect static pressure for optimal performance of your system is 0.5 inches per WC.

Why is it Important to Calculate Static Pressure in an HVAC System?

It’s essential to know the static pressure of an HVAC system because having it too high or too low can be detrimental to the proper functioning of the system. It’s therefore important to calculate static pressure for the following reasons:

To Identify Airflow Problems Within the Duct

Knowing static pressure helps installers understand whether there’s adequate airflow in the ductwork or whether there’s a struggle. Once you have identified the airflow issue, you will be able to pinpoint the source of the problem in a client’s furnace, air conditioner or heat pump system. You will then check if the installation was done correctly and if it’s the right size.

Elevated static pressure may be caused by a blockage in the ductwork, restrictive filters and closed dampers. If the static pressure is too low, it indicates a leak caused by a low fan speed, separated duct and missing filters. And to avoid future problems, good maintenance and ensuring that the furnace and ductwork are free of airflow issues are necessary.

To Prevent Damage to the Equipment

The compressor is likely to burn due to constrained airflow and replacing it is an expensive affair. Also, static pressure diminishes the lifespan of the equipment.

To Determine System’s Efficiency

The higher the static pressure, the less efficient your system will perform, and the energy bills will go up. A less effective system will also affect the comfortability of a house because it will either be too hot or too cold.

What Causes Disruptions to Static Pressure?

Disturbances to static pressure can be caused by various issues including:

Sizing of the Ductwork

If the ductwork is undersized or unprofessionally designed, the system will not perform well. Both oversized and undersized ductwork pose a problem.

The primary issue with undersized ductwork is the air returns, a crucial part of the air circulation process because they pull air from the room and remit it to your heating or cooling system.

If the air return duct is small, it will work harder to pull the quantity of air needed for circulation. This will eventually lead to system breakdown and expensive repairs.

On the other hand, ductwork that is too big will lead to low static pressure because there isn’t adequate pressure to pull air to distant air grates. This results in uneven conditions in a house (too cold or too hot).

Improper Ductwork Installation and Design

Badly designed ductwork will lead to increased airflow counteracting and elevated static pressure.

Studies show that nine out of 10 HVAC systems are poorly installed.

Clogged Ductwork and Dirty Filters

Substantial amounts of dust and dirt will make them narrower thus increasing static pressure.

Air filters act like screens to trap dirt particles that may affect HVAC systems and add useful resistance. However, after months of use without changing, the filters get clogged and the resistance negatively affects the optimal performance of your system.

If your filter is thick, it is dirty, leading to increased static pressure.

Pleated Filter Size

Small, pleated filter sizes and thickness will increase airflow resistance.

What Problems Arise From Improper Static Pressure?

Having improper static pressure has consequences. Some of the consequences are:

Uneven Heating and Cooling

Inappropriate static pressure will cause a temperature variance leaving some rooms cold and others hot. This is known as cold and hot spots and is caused by weak airflow in one or more parts of the system. As a result, the air is unable to travel through the ductwork and can’t reach every room efficiently.

Air Quality Issues

Since airflow is unable to travel efficiently through the ductwork, air in a room becomes stale due to lack of circulation.

Premature System Failure

High static pressure means that the blower motor and the compressor are working harder than intended and will wear out soon. Additionally, if the system is heating and is unable to get rid of that heat quickly, other internal problems will occur, like untimely cracks in the heat exchanger.

How to Alleviate Problems with Static Pressure

The following ideas will help solve the problem of too much and too low static pressure:

Ductwork Modification

The ductwork can be redesigned at the beginning of the furnace by installers during installation. This is because airflow is vigorous at the opening.

Usually, most ductworks coming from a furnace have a 90-degree turn fitting. This is where the vertical furnace meets the horizontal duct, then runs to the basement and breaks into different individual lines. However, a 90-degree turn fitting often limits airflow. A 45-degree turn is recommended because it has less airflow resistance.

Regular Air Filter Maintenance

To avoid equipment failure and ensure energy efficiency, HVAC systems must be regularly and thoroughly cleaned. You can schedule the time for the routine cleaning. Look out for dust and dirt in the vents, as this indicates clogged ductwork. Also, pay attention to any cracks or holes in the ductwork that indicate a leak.

Increase Return Airdrop

Nearly all return drops are undersized, thus resisting airflow. But, by increasing these ducts, airflow passes on correctly with less resistance.

Conclusion

The HVAC system size and design are important as they impact maintenance, energy bills, and operation costs. A sound functioning system guarantees comfort in a home.

Poor system design and installation can be the root cause of most static-pressure-related HVAC problems. It’s therefore critical that contractors and installers understand precisely how static pressure within the HVAC system functions so that they can effectively troubleshoot, maintain and repair it.

There you have it! Aspects of an HVAC system explained in a nutshell. Subscribe to the Construction Fanatics newsletter to get more informational content.